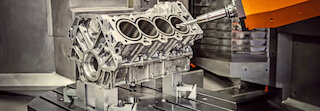

The particular challenge in the automotive and aerospace industries is to maintain stable climate control during production processes, e.g. in foundries, on production lines, in production machinery and in paint shops. These industries are subject to a constant need for optimisation and have to ensure that they use the most efficient methods and eco-friendly products. Stable climate control and adjustable air humidity play a key role in these processes.

WE HUMIDIFY THE AIR

The advantages of air humidification in the automotive and aerospace industries

-

- Vehicle paintwork using water-based coloured lacquer requires precise, reliable temperature regulation and humidity conditions in the paint shop.

- The use of new materials such as carbon fibre requires stable and accurate air humidity control.

- Ensures the necessary environmental conditions to test the durability of mechanical and electronic components under extreme conditions.

- The risk of disruption to production processes and equipment because of electrostatic discharge is avoided with a relative humidity of at least 40%.

- A comfortable climate of 40-60% relative humidity increases productivity and also helps reducing employees’ health-related absences.

Products for this application

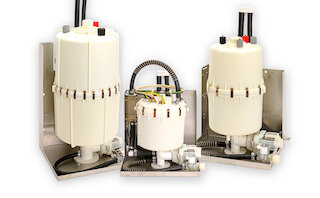

Electrode steam humidifiers

Atomiser humidifiers

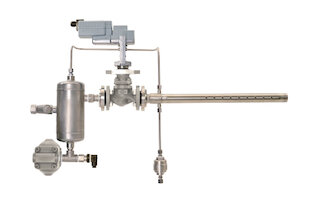

Steam injection humidifier

Heater type steam humidifiers

Downloads

Brochures

HygroMatik –

We humidify the air.

We humidify the air.

Company brochure

Planning brochure

Planning healthy indoor air

Useful information for planners