Even the basic version of our FlexLine series is characterised by solid basic functions, long operating times and a long service life. As an option, all FlexLine units can be customised at the factory with over 100 additional function combinations to meet the needs of the installation environment. Most FlexLine options can also be retrofitted or activated later. This means that you only invest in the humidifier version that you actually need.

Air humidification systems flexibly configured –

FlexLine options

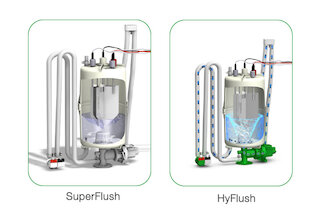

SuperFlush or HyFlush

Effective protection for the steam cylinder

SuperFlush or HyFlush

The FlexLine options SuperFlush and HyFlush are intelligent cylinder flushing functions that effectively protect the cylinder and supply lines of your FlexLine steam humidifier from deposits. These are caused by mineral ingredients (e.g. calcium, magnesium, etc.) in the tap water during heating and evaporation. During the blow-down process, a powerful jet of water loosens hardness formers from the cylinder base, whirls them up and thus ensures improved discharge.

HyFlush works with a stronger water jet than SuperFlush. This ensures an even more effective cleaning process and faster refilling of the cylinder. The SuperFlush cylinder flushing function is already integrated as standard in the FlexLine FLH and FLP versions.

With clear advantages

-

- Execution of cylinder flushing during operation reduces the downtimes of the system

- Less maintenance work and longer maintenance intervals

- Longer service life

- Lower operating costs

FlexLine options

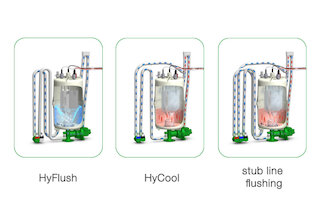

HyFlush, HyCool, stub line flushing

Maximum protection for cylinders and lines

HyFlush, HyCool und Stichleitungsspülung

The FlexLine options HyFlush and HyCool effectively protect the cylinder and waste water pipes from deposits. Depending on requirements, HyFlush and HyCool can also be installed individually. In addition, a stub line flush is also possible, which prevents the supply line from becoming contaminated by standing water during longer downtimes in accordance with VDI 6022.

The HyFlush flushing function dissolves and removes deposits in the cylinder caused by mineral substances (e.g. calcium, magnesium etc.) in the tap water during heating and evaporation. This enables an even longer operating time between maintenance intervals.

The FlexLine HyCool option protects the waste water pipes by reducing the waste water temperature to below 60°C. This is particularly important if, for example, the waste water pipe is not made of high temperature resistant material on site or if a lifting unit is used. The lower waste water temperature also significantly reduces vapour formation in the free outlet of the drain funnel. This enables installation in narrow niches or poorly ventilated technical cabinets.

With clear advantages

-

- Lower operating costs due to less wear

- Lessmaintenanceworkandlongermaintenanceintervals

- Protection of waste water pipes from excessive thermal loads

- Improved hygiene thanks to stub line flushing

- Longer service life

FlexLine option

Safety chain 12V / 24V / 230V

Flexible voltage specification

Safety chain 12V / 24V / 230V

To prevent damage and overloading of the air humidification system and to ensure the safety of people and property, different safety sensors such as flow monitors, leakage monitors or thermostats are integrated in a safety chain of the control system. Only when all sensors confirm safe operation the safety chain is closed and the steam humidifier can start.

Depending on the voltage specified by existing sensors or the BMS system, you can choose between 12V / 24V and 230V. With this FlexLine option, we offer the right solution for every standard voltage in the safety chain.

With clear advantages

-

- Adaptation of the voltage in the safety chain to existing components or a BMS system

- Avoidance of time-consuming and costly adaptation measures to existing technology, national regulations and standards

- Prepared for quick installation of the safety chain

FlexLine options

Communication via BACnet / Modbus

System monitoring and control

via BACnet or Modbus

With this FlexLine option, the humidifier can be integrated into an existing bus network via an RS485 interface as a BACnet MSTP server or as a Modbus RTU server. The RS485 interface is adjustable and galvanically isolated.

If integration takes place via BACnet, error messages and values can be read out and made available in the network. If the connection is made via Modbus, additional control functions are also available.

With clear advantages

-

- Simple connection to an existing network or BMS system

- Centralised integration of several building systems through standardised communication protocols

- Information and values can be clearly prepared and displayed

- Centralised monitoring and control functions

FlexLine option

External 3.5“ remote touch control display

External operation, control and configuration

via external 3.5“ remote touch control display

The FlexLine 3.5“ Remote Touch Control Display option enables complete operation, control and configuration of the devices in our FlexLine series, spatially separated from the steam humidifier. All settings and information that can be read out or carried out directly on the device can thus be done 1:1 remotely. This option is the ideal solution for convenient and reliable operation if the steam humidifier installation is difficult to access. The remote touch control display can also be quickly and easily integrated into a centralised remote desk.

The connection to the steam humidifier is established via Modbus RTU. The housing corresponds to class IP65 when installed accordingly. A VESA 75 wall bracket is supplied for quick and clean surface mounting.

With clear advantages

-

- Complete remote operation, control and configuration

- Ideal solution for installations that are difficult to access and centralised remote desks

- IP65 housing - with appropriate installation

- Surface-mounted solution incl. VESA 75 wall bracket

FlexLine option

Control of parallel devices

Control of parallel devices

via one device unit

If several individual humidifiers are required for a high humidification output, they can be operated in parallel (all run simultaneously at the same output) or in sequence (1st unit starts, from e.g. 25% demand the 2nd unit is switched on, etc.) with this FlexLine option with one single control signal and one release like a large humidifier. To be able to use this retrofittable FlexLine option, all humidifiers must be equipped with the option.

With clear advantages

-

- Simple scaling of the humidification capacity

- Less effort required for installation, commissioning and configuration

- Time and cost savings when adapting the system

- Only one release contact required in the BMS control system

FlexLine option

Digital input for service messages

Digital input for service messages

from the safety chain

The switching contacts of the hygrostat, air vane, pressure box or a leakage monitor are often connected in series and connected to terminals 1 and 2 for safety shutdown. In the event of an open safety chain, it is not possible to determine which switching contact has opened due to the series connection.

With this FlexLine option, each switching contact has its own connection terminal and is recorded separately from the control system via a digital input. Each digital input is assigned a switching contact function in the parameterisation. When the switching contact is open, the corresponding message is shown on the display as a service message. The parameters can be set directly via the 3.5‘‘ touch display on the humidifier.

With clear advantages

-

- Detailed system information available at a glance

- Simplified troubleshooting and faster response times in the event of faults

- Avoidance of long downtimes or operational failures

- Reduced service costs

FlexLine option

Freely programmable signalling relays

Freely programmable signalling relays

for extensive signalling functions

Depending on the application and connection to higher-level or upstream / downstream components and systems, the humidifiers can trigger numerous signalling and control functions via relays. If the standard signalling relay (factory used for signalling a collective fault) is not sufficient, this FlexLine option can be used to install up to 2 x 2 additional relays for switching further functions or messages.

The relays are simply mounted on the top-hat rail in the humidifier. The switching function of the relays is freely programmable. The parameters for this can be conveniently set directly via the 3.5‘‘ touch display on the humidifier.

With clear advantages

-

- Extended monitoring function provides additional system information

- Freely programmable, customised configuration

- Messages can be sent directly to the customer

FlexLine option

Wide range control (for heater version)

Wide range control (heater version)

Large performance range - precisely controllable

With this option, FlexLine heater humidifiers have a controllable power reduction to reduce the heat output for low requirements below 33%. This triples the control accuracy of the humidifier in this range and the humidifier can also control significantly lower outputs very precisely.

With this T-PRO option, the FlexLine heater wide range control reduces the smallest controllable steam output by 300% compared to a standard humidifier.

This FlexLine option can only be activated at the factory.

With clear advantages

-

- Despite a large output range, the wide range control enables precise and stable control of the humidification output with low power output

- Ideal for use in test laboratories and simulation systems

FlexLine option

Digital input water inlet pressure

Digital input for water inlet pressure

to prevent malfunctions

This FlexLine option avoids unnecessary malfunctions due to insufficient water inlet pressure. The humidifier may only go into operation if there is a water inlet pressure of > 1 bar at the solenoid valve. To ensure this, a pressure sensor activates the digital input when the water pressure is correctly applied. If the pressure drops, this deactivates the digital input and interrupts the humidification request.

Instead of going into fault mode, a service message is issued indicating that the pressure at the water inlet has fallen below the minimum pressure. The parameters for this FlexLine option can be set directly with the 3.5“ touch display on the humidifier or with the 3.5“ remote touch control display.

With clear advantages

-

- Fast troubleshooting and rectification through service messages

- Reduction of malfunctions and downtimes

FlexLine option HyLevel

Water level sensor for electrode humidifier

Prevention of increased electrode burn-off

and decrease of performance thanks to

capacitive water level detection

Depending on the water quality, the cylinder water sometimes tends to foam when boiling or form salt bridges in the upper of the cylinder. In this case, the sensor electrode signals a full cylinder level to the control unit, although the actual water level in the cylinder is significantly lower. This ‘false’ cylinder full signal leads to a reduced blow-down rate and a drop in performance. This increases the conductivity in the cylinder water and causes increased electrode burn-off.

The modularity of our housings enables the installation of a water level sensor. This allows the control unit to validate the cylinder level, ignore it if necessary and generate a service message at the same time. This allows the blow-down routine to work undisturbed and effectively.

With clear advantages

-

- Enables validation of the cylinder full message

- Prevents disruption of the blow-down routine

- Prevention of performance drops

- Prevention of increased electrode burn-off

- Less maintenance work and longer maintenance intervals

- Lower operating costs due to reduced wear

FlexLine option

Electrode version with demineralised water

Operation with demineralised water

for electrode steam humidifiers

Electrode steam humidifiers are usually operated with ordinary tap water. In addition to pure H2O, tap water also contains minerals (e.g. calcium, magnesium, etc.). When water is heated and vaporised, these precipitate as sludgy or crystalline deposits that remain in the steam cylinder and must be removed during regular maintenance. As the water must have a certain conductivity for the vaporisation process using electrodes, it is often not possible to use demineralised water purified of these mineral ingredients in electrode steam humidifiers, despite the many advantages.

This FlexLine option uses a patented process to add demineralised water to the tap water in an optimum ratio, which ensures the conductivity required for stable operation. At the same time, however, the loss of hardness formers is reduced to a minimum, which enables a significantly longer operating time between two maintenance intervals.

With clear advantages

-

- Lower investment costs than when using heating elements

- Lower operating costs due to less wear and tear

- Lower maintenance costs and longer maintenance intervals

- Longer service life

FlexLine option (for FLH Plus and Process)

Temperature sensor and HyTherm

Up to 80% energy savings

with temperature sensor and HyTherm

The HyTherm option is available for all stainless steel cylinders in our FlexLine Plus / Process series heater humidifiers. An additional insulating cylinder jacket significantly reduces heat radiation from the steam cylinder.

An additional temperature sensor between the cylinder and the HyTherm cylinder casing records the temperature at the cylinder. This enables the control unit to perform standby heating, without having to go into pulse-pause mode. Stand-by heating helps to maintain the specified operating temperature and prevents the temperature from dropping during the steam production process.

With clear advantages

-

- Sustainable and environmentally friendly with up to 80% less heat loss

- Savings in operating costs thanks to lower energy consumption

- Effective protection against accidental contact, especially during maintenance work

- Quick and easy installation thanks to practical Velcro fastener

FlexLine option

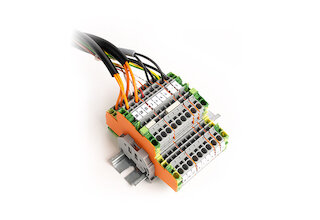

Pre-wired connections on terminal block

Safe and quick installation

with pre-wired connections on terminal block

In certain applications (e.g. ship installations), terminals on a top-hat rail are required for the transfer of operating messages to the BMS. With this option, the FlexLine steam humidifier is equipped with pre-wired connections on additional terminals. These enable, for example, the connection of a separate control voltage L N, the safety chain, the signalling relays and provide analogue inputs for reporting collective faults.

With clear advantages

-

- Safe and quick installation

- Pre-wired connections on terminal block

Downloads

– HyFlush, HyCool, stub line flush –

(Electrode and Heater Type Steam Humidifiers)

3,5“ display

(Insulating cylinder coat)

– Customise your FlexLine –

(cylinder rinsing system)